This integration ensures a design change made anywhere in the process from concept to production will reflect everywhere.

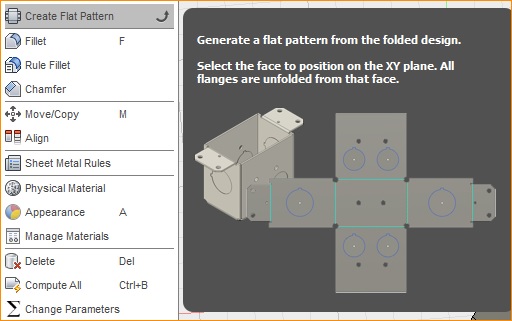

Fusion 360 sheet metal unfold drawing.

The portion of the model in question is located on the end of the flange.

When selecting the unfold command the model body becomes transparent.

You might also use the render or drawing workspaces.

Keeping the features grouped makes it simple to roll back and update later.

Fusion 360 has several different workspaces that give you access to different sets of tools.

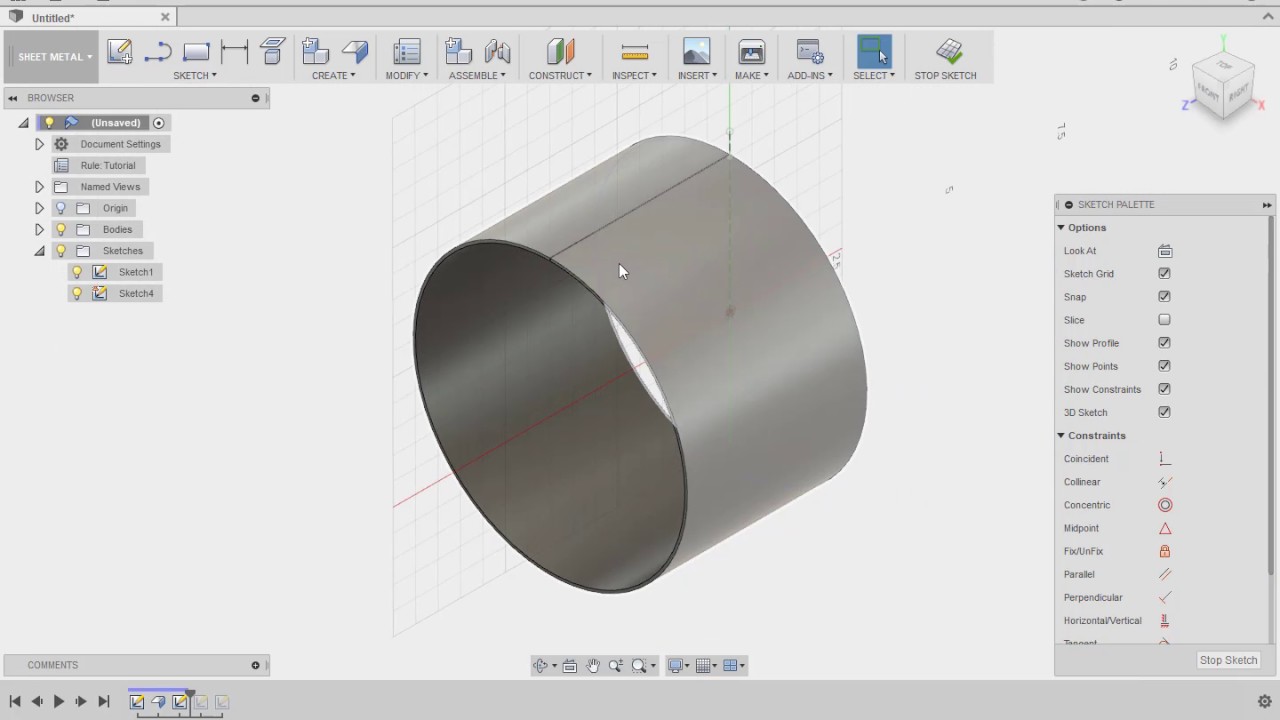

Only sheet metal bodies can be unfolded.

But for the purpose of this instructable we ll show how to make this workflow work for parts that aren t actually sheet metal parts.

1 create a plane above your part at some set distance.

Unable to unfold a part in fusion 360.

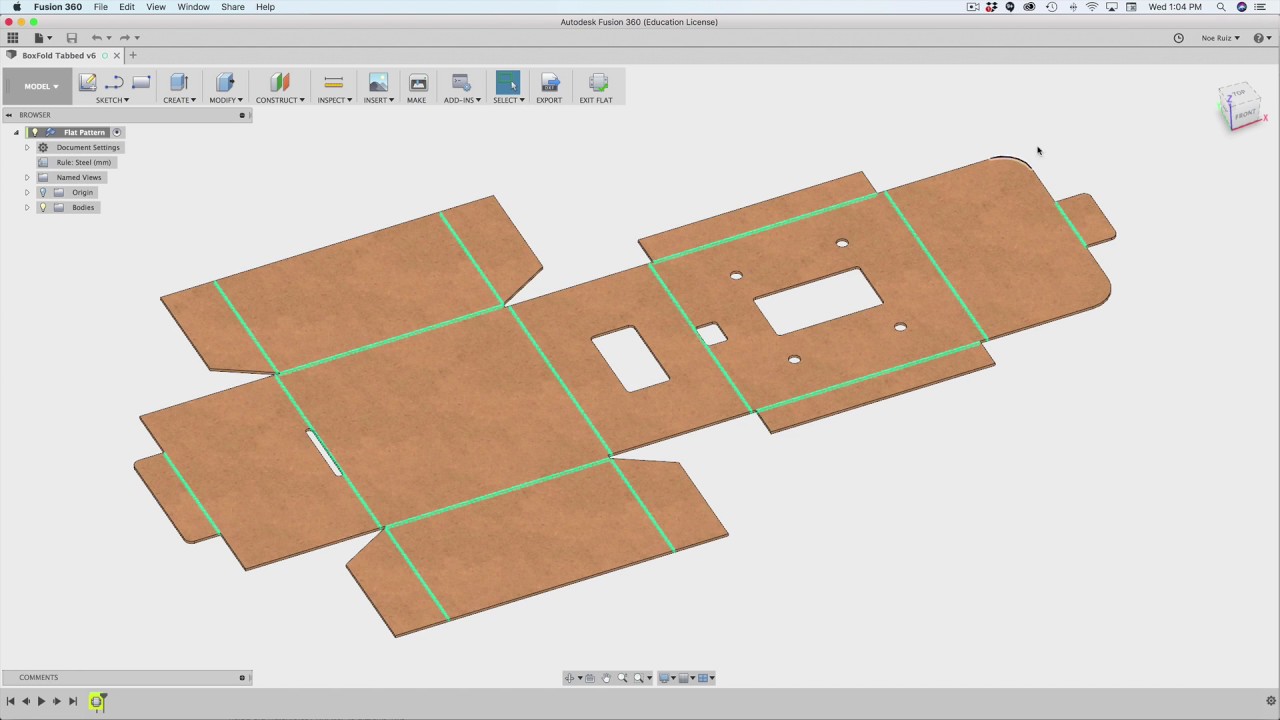

But fusion 360 doesn t just integrate the process from design to flat pattern.

So you ll unfold create your cuts then refold.

The body is a brep body rather than a sheet metal body.

It was exactly the right tool for what i needed.

While there is not currently a way to fully omit bend lines from a 2d drawing of a sheet metal flat pattern in fusion 360 there are a number of ways to work around this limitation.

A component may be shown as a sheet metal component but there may be a.

Omit bend extent lines omitting bend extent lines will not fully remove bend lines but will give only one line per bend rather than three.

Now you get why fusion 360 s sheet metal is different.

In creating the latest sheet metal part i found a reason to try out the unfold refold functions in fusion 360.

Everything between the unfold and refold will be grouped in the timeline.

Where fusion 360 will be different is the unfold command will be a mode similar to sketch or sculpt.

To unfold the body convert the body to a sheet metal part.

The one you are most familiar with is the model workspace in which you can create sketches and three dimensional geometries.